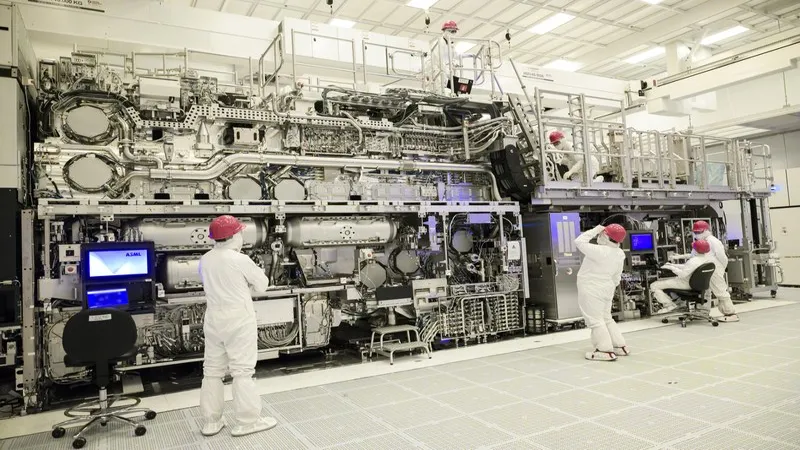

In the fiercely competitive landscape of semiconductor manufacturing, Intel is making bold moves to reclaim its status as a process technology leader, a position it lost to rivals TSMC and Samsung. With the recent acquisition of ASML’s groundbreaking High-NA EUV lithography machines, Intel is poised to revolutionize its chip production capabilities. These advanced machines promise not only enhanced precision but also significant reductions in production time and costs, allowing Intel to push the boundaries of chip design. As the company embarks on this critical journey towards its 18A process node, it stands at a pivotal moment in its quest to dominate the future of chip technology once again.

| Attribute | Details |

|---|---|

| Company | Intel |

| Technology | High-NA EUV lithography |

| Original EUV Delivery | $400 million for the second generation |

| Key Feature | Increase in numeric aperture from 0.33 to 0.55 |

| Manufacturing Capability | Chips using process nodes below 3nm |

| Efficiency Improvement | Fewer exposures, reduced processing steps |

| Production Status | First two High-NA machines in production |

| Wafers Produced | 30,000 wafers produced using High-NA machines |

| Competitors | TSMC and Samsung Foundry |

| Upcoming Production | Intel’s A18 node to start in the second half of 2025 |

| Key Technology Advantage | Backside Power Delivery (BSPD) feature, branded Power Via |

| Future Plans | Testing High-NA machines for 14A node; no production date yet |

Intel’s Leap into New Technology

Intel has taken a significant step forward by embracing the latest High-NA EUV lithography machines. These advanced machines are crucial for creating smaller and more efficient chips. By using this technology, Intel aims to produce chips with features smaller than 3nm, a feat that allows for a higher density of transistors. This means that more powerful and energy-efficient devices can be made, benefiting consumers with faster and longer-lasting technology.

The journey to adopting this new technology wasn’t easy, but Intel is determined to regain its position as a leader in chip manufacturing. With the delivery of the High-NA EUV machines, Intel has the potential to significantly increase production efficiency. Unlike previous machines that required multiple exposures, the new ones can produce chips with fewer steps, saving both time and resources. This shift is vital for Intel as it competes against rivals like TSMC and Samsung.

Understanding Lithography in Chip Production

Lithography is a key process in making computer chips. It involves transferring patterns onto silicon wafers, which are the building blocks of all electronic devices. The introduction of High-NA EUV lithography machines has revolutionized this process. These machines create sharper images and allow for much smaller features on chips, which is essential for modern technology. The ability to work with smaller transistors means that chips can perform better while using less power.

By using the latest lithography technology, companies like Intel can produce chips that are not only faster but also more efficient. This is particularly important as devices continue to demand more processing power. The efficiency gained from High-NA EUV machines means that manufacturers can produce more chips in less time, which ultimately helps meet the growing global demand for advanced electronics. This process is vital for keeping up with the fast-paced world of technology.

The Race for Process Leadership

The competition among chip manufacturers has reached an exciting peak, especially between Intel, TSMC, and Samsung. Each company is trying to be the first to produce the latest technology, which can lead to better performance in devices. Intel is focused on reclaiming its process leadership, especially with its new A18 node, which promises to rival TSMC and Samsung’s upcoming 2nm nodes. This race is crucial, as being the first can mean significant advantages in the market.

Intel’s strategy includes leveraging unique features like Backside Power Delivery, which allows for improved power efficiency in chips. This innovation will help Intel stand out in the competitive landscape. As the company prepares for mass production of its new chips, it aims to establish itself as a leader once again. The stakes are high, and Intel’s success or failure could shape the future of technology and how we use it every day.

The Importance of Efficient Production

Efficiency in chip production is essential for companies to stay competitive. The High-NA EUV machines are designed to improve production speed significantly. By reducing the number of steps needed to create chips, Intel can deliver products to market more quickly. This is vital in a field where technology evolves rapidly, and consumer expectations are high for faster and more powerful devices.

Moreover, efficient production processes help reduce costs. By using fewer resources and time, Intel can offer competitive prices for its chips. This not only benefits the company but also the consumers, who will enjoy advanced technology at more affordable prices. As Intel continues to refine its manufacturing processes, the focus remains on delivering high-quality products that meet the demands of today’s tech-savvy world.

Challenges and Opportunities Ahead

Despite its advancements, Intel faces several challenges on its path to reclaiming leadership. The company has struggled in the past with delays in adopting new technologies, which allowed competitors to catch up and even surpass them. However, with the commitment to using High-NA EUV machines, Intel is poised to overcome these hurdles. The opportunity to produce chips with higher efficiency and lower costs presents a chance to regain lost ground.

Furthermore, the rapid pace of technological change means that Intel must remain vigilant. Competitors are constantly innovating, and any misstep could jeopardize Intel’s position in the market. However, the introduction of innovative features like Backside Power Delivery and the use of cutting-edge lithography are steps in the right direction. By addressing past mistakes and leveraging new technology, Intel can position itself for success in the dynamic world of semiconductor manufacturing.

Looking Forward: Intel’s Future Plans

Intel’s future plans revolve around maximizing the potential of its new High-NA EUV lithography machines. The company aims to utilize these machines in producing its 18A process node, which is crucial for upcoming products like the Panther Lake chip. This chip is expected to cater to the growing demand for powerful notebook computers. By focusing on high-performance technology, Intel is setting the stage for a successful future.

Moreover, Intel is committed to continuous improvement and innovation. As they roll out the new chips, rigorous testing will ensure that each product meets high standards. The company’s goal is not just to catch up but to lead the way in semiconductor technology. With a focus on efficiency and performance, Intel’s future looks promising as it aims to reshape the landscape of chip manufacturing for years to come.

Frequently Asked Questions

What are High-NA EUV lithography machines?

High-NA EUV lithography machines are advanced tools used in chip manufacturing that allow for smaller and sharper circuitry patterns on silicon wafers, enabling chips with process nodes below 3nm.

How does High-NA EUV technology benefit Intel?

The High-NA EUV technology saves Intel time and money by requiring fewer exposures and processing steps to print designs, improving efficiency in chip production.

Why is Intel investing in new lithography machines?

Intel is investing in new High-NA EUV machines to regain leadership in chip manufacturing process technology, after previously losing ground to TSMC and Samsung.

What is the significance of the Backside Power Delivery (BSPD) feature?

The Backside Power Delivery feature improves power efficiency by relocating wiring, allowing transistors to operate at higher speeds, enhancing chip performance.

How many wafers has Intel produced with High-NA machines?

Intel has produced approximately 30,000 wafers using the new High-NA lithography machines, each containing thousands of chips.

What is Intel’s 18A process node?

Intel’s 18A process node is a new technology for chip production that utilizes High-NA EUV machines and is set to begin mass production soon.

How does Intel’s position compare to TSMC and Samsung?

Intel aims to regain process leadership from TSMC and Samsung Foundry by utilizing innovative technologies like High-NA EUV and Backside Power Delivery.

Summary

Intel is working hard to regain its leadership in chip manufacturing, focusing on advanced technology with the new High-NA EUV lithography machines from ASML. These machines allow Intel to produce smaller and more powerful chips by requiring fewer steps and saving time in the manufacturing process. Recently, Intel announced that they are already using these machines to produce chips, achieving a consistent output of 30,000 silicon wafers. With new features that improve efficiency, Intel aims to compete with TSMC and Samsung in the race for the latest chip technology, avoiding past mistakes that cost them their lead.